The Altus approachto growth is

to create long-term value

October 10, 2023

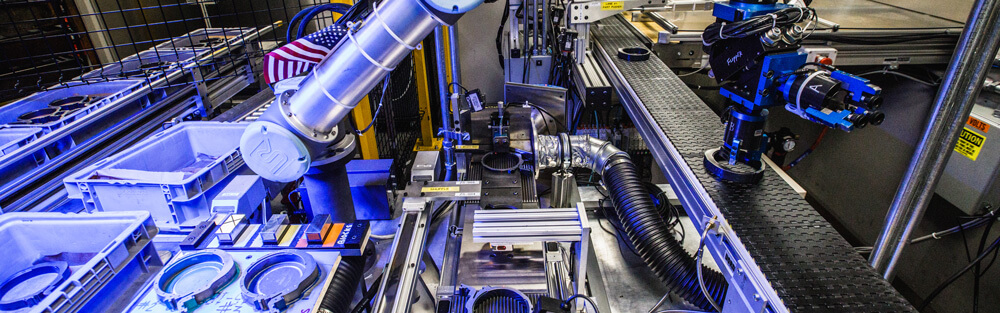

Investment and Installation - (2) 3700T Machines

Thomson Plastics, Inc. (“TPI”) is pleased to formally announce the investment and installation of two new 3,700-ton injection molding machines for our southern locations.

The purchase is the latest in the fulfillment of our Company’s strategic plan to refresh the fleet of injection molding equipment across all facilities by the end of 2026.

According to Thomson Plastics, Inc. President and CEO, Steve Dyer, “Long-term investments are critical to TPI’s ongoing commitment to exceeding customer expectations in quality, cost, and customer service.”

“These new presses are faster and are significantly more efficient. They use 40% less energy than the older vintage machines. In all, they just produce a more consistent and a higher-quality product,” said Dyer of the upgrades. “That consistency and quality is what will continue to take care of our marquee customers. We’re working to step up our game because they’re all growing and expanding and their expectations of us are growing — and rightfully so. We will also be looking for many new customers.”

This effort comes on the heels of a Year One investment in five new production machines during 2022. Three machines ranging in capacities between 1,000 and 1,980 tons were installed at the Thomson headquarters while two 400-ton machines were brought online at TPI’s Lexington, NC, facility.

Although there are thousands of companies that can turn plastic pellets into parts, TPI is one of only a handful that can employ as much as 4,400 tons of clamping force.

“Our mission is to be the leader in large tonnage injection molding in the southeast. Period, end of sentence,” said Dyer.

Media Contact

Matthew Key

Director of Program Management

706-595-0658 ext. 1110

[email protected]